"Duck Duck Grey Duck FTMFW!" (theduckduck)

"Duck Duck Grey Duck FTMFW!" (theduckduck)

04/25/2018 at 08:46 ē Filed to: None

2

2

21

21

"Duck Duck Grey Duck FTMFW!" (theduckduck)

"Duck Duck Grey Duck FTMFW!" (theduckduck)

04/25/2018 at 08:46 ē Filed to: None |  2 2

|  21 21 |

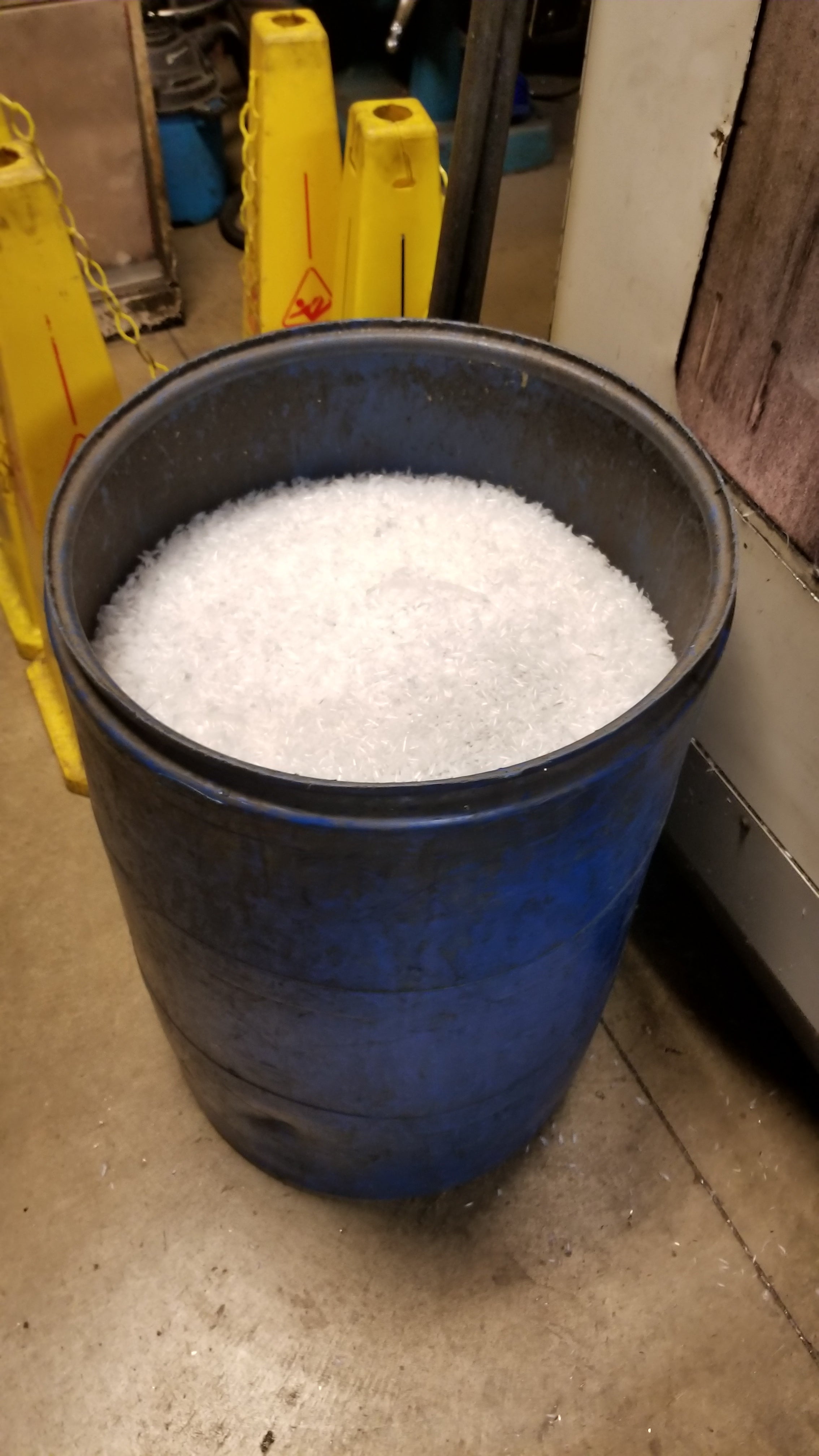

One down, three to go.

They are 28x8.5x3 blocks of UHMW.

The fruit of my labor.

vondon302

> Duck Duck Grey Duck FTMFW!

vondon302

> Duck Duck Grey Duck FTMFW!

04/25/2018 at 09:02 |

|

Fun to machine not fun to clean up after.

diplodicus

> Duck Duck Grey Duck FTMFW!

diplodicus

> Duck Duck Grey Duck FTMFW!

04/25/2018 at 09:06 |

|

Some sort of chain guide?

Spanfeller is a twat

> Duck Duck Grey Duck FTMFW!

Spanfeller is a twat

> Duck Duck Grey Duck FTMFW!

04/25/2018 at 09:08 |

|

A variation of that material called Dyneema is used for bulletproof application.

benjrblant

> Duck Duck Grey Duck FTMFW!

benjrblant

> Duck Duck Grey Duck FTMFW!

04/25/2018 at 09:19 |

|

Could that shape not be heated and formed or vacuum-formed? Seems like so much milling for such a simple part!

Duck Duck Grey Duck FTMFW!

> vondon302

Duck Duck Grey Duck FTMFW!

> vondon302

04/25/2018 at 09:21 |

|

Lol, I just posted the 55 gallon barrel worth of chips

Duck Duck Grey Duck FTMFW!

> benjrblant

Duck Duck Grey Duck FTMFW!

> benjrblant

04/25/2018 at 09:22 |

|

I honestly donít know. I only just started going back to school to get a degree in mechanical engineering. Not sure if I would learn that. Will get back to you in 4+ years.

Future next gen S2000 owner

> Duck Duck Grey Duck FTMFW!

Future next gen S2000 owner

> Duck Duck Grey Duck FTMFW!

04/25/2018 at 09:29 |

|

You probably wonít learn it either. ME degree is much more the nuts and bolts of how to design/analyze something. Not necessarily the best way to do something.

For custom pieces, milling makes sense. Manufacturing environment would mold the pieces or extrude them.

MrDakka

> benjrblant

MrDakka

> benjrblant

04/25/2018 at 09:38 |

|

Not necessarily. IIRC UHMWPE can be made to have anisotropic properties so depending on the application, heating the part would ruin itís crystallinity. It could be Iím also spouting complete BS until we can get a material engineer in here.

Alfalfa

> benjrblant

Alfalfa

> benjrblant

04/25/2018 at 09:45 |

|

Yes, but initial cost for such a thing is going to be a bit much. You want to make sure itís for something that you will be needing a lot of for that initial $ to be worth it.

DasWauto

> benjrblant

DasWauto

> benjrblant

04/25/2018 at 09:52 |

|

UHMW can be made to specific shapes in a high pressure/heat press from its base granules but you need enough volume of parts to make the cost of the molds/dies worthwhile. For a smaller number of parts, machining from standard stock sizes is much more cost effective.

jimz

> benjrblant

jimz

> benjrblant

04/25/2018 at 10:00 |

|

if you only need a small number of parts, itís cheaper to do it this way (or to do it via additive manufacturing/3D printing) than it is to design and make dies/molds youíll only use once.

plus, if the material can be recycled you win some of it back.

benjrblant

> DasWauto

benjrblant

> DasWauto

04/25/2018 at 10:06 |

|

Ah, I knew it could be injection molded but wasnít sure about heat or vacuum forming.

Long-Voyager

> Duck Duck Grey Duck FTMFW!

Long-Voyager

> Duck Duck Grey Duck FTMFW!

04/25/2018 at 10:14 |

|

It makes a mess, but itís a riot to machine.

TorqueToYield

> Spanfeller is a twat

TorqueToYield

> Spanfeller is a twat

04/25/2018 at 10:15 |

|

UHMW is a really interesting material.

Itís also used in knee and hip replacements as the main bearing surfaces.

Spanfeller is a twat

> TorqueToYield

Spanfeller is a twat

> TorqueToYield

04/25/2018 at 10:23 |

|

Much lighter and resistant than Kevlar.

oldmxer

> benjrblant

oldmxer

> benjrblant

04/25/2018 at 10:34 |

|

you have to have an iron clad contract to make uber number of parts to justify the huge expense of making dies, in the old days it was quite a crap shoot but with digital control mills and lathes short runs are negotiated and both parties are happy, especially with materials such as plastic which can be done in a fraction of time of what harder materials require

Duck Duck Grey Duck FTMFW!

> diplodicus

Duck Duck Grey Duck FTMFW!

> diplodicus

04/25/2018 at 11:04 |

|

Honestly not sure. Itís called a roller guard by the customer.

Duck Duck Grey Duck FTMFW!

> Long-Voyager

Duck Duck Grey Duck FTMFW!

> Long-Voyager

04/25/2018 at 11:05 |

|

Lol. 150 IPM? why not.

Long-Voyager

> Duck Duck Grey Duck FTMFW!

Long-Voyager

> Duck Duck Grey Duck FTMFW!

04/25/2018 at 11:59 |

|

150 IPM is all?

Thatís what we run our .750 3-flute aluminum cutter at in this stuff. Otherwise we use our Franken Rhombic cutter. 11000 rpms, 360 ipm. Iíve pushed .150sd/.250so with it, but we usually run .05sd/.200-.700so.

Duck Duck Grey Duck FTMFW!

> Long-Voyager

Duck Duck Grey Duck FTMFW!

> Long-Voyager

04/25/2018 at 12:31 |

|

Eh, it worked for this job. Was worried about chatter. Guess I could have done a faster rate and slowed it down for the last few passes. Oh well. What do you mean by sd and so(.05sd for example). I am not a trained CNC machinist. I learned on the job so there are some lot of acronyms I donít know.

Long-Voyager

> Duck Duck Grey Duck FTMFW!

Long-Voyager

> Duck Duck Grey Duck FTMFW!

04/25/2018 at 12:33 |

|

Step Down (sd) and Step Over (so).

Usually use the rhombic for roughing and the 3/4 for finishing. Never had an issue with chatter and our 3/4 is 3.25" long.